How does the magnetostrictive displacement sensor work?

Magnetostrictive displacement sensor is a displacement sensor with high precision and long stroke azimuth measurement, which is made according to the principle of magnetoelasticity. The magnetostrictive displacement sensor consists of two parts: one is a measuring rod with a movable magnet; The other part is the measuring circuit located at the upper end of the measuring rod.

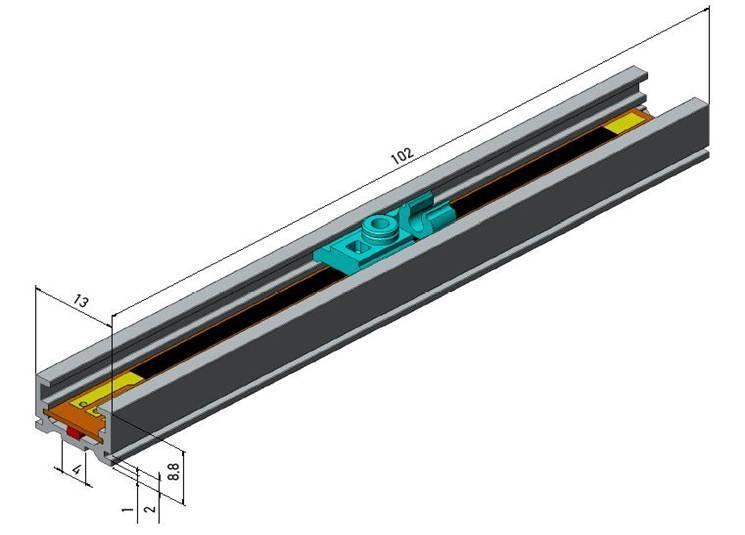

Magnetostrictive displacement sensor mainly includes the following parts: waveguide wire, maintenance tube sleeve, mobile magnet and circuit board. The measuring tube is the central sensing part of the whole sensor, which also includes: bias magnet, waveguide wire, maintenance tube sleeve, end attenuation damping equipment, non-contact magnetic ring, converter output.

The magnetoelastic line is installed in the stainless steel tube, and the outside of the steel tube can slide freely. The pulse generator in the electronic equipment generates current pulses (starting pulses) and transmits them along the wave conductor. The generated magnetic field is superimposed with the inherent magnetic field vector of the movable magnetic ring to form a spiral magnetic field, which generates an instantaneous torque, twists the waveguide line and generates a tension pulse (waveguide pulse), which is transmitted back along the waveguide at a fixed speed, The induction pulse (stop pulse) is generated at both ends of the coil (converter), and the measured displacement can be accurately determined by measuring the time difference between the start pulse and the stop pulse. Because the velocity of the tension pulse on the waveguide is stable, multiply the measured time difference by this velocity to obtain the orientation of the magnetic ring. This process is continuous. Whenever the magnetic ring moves, the new orientation will be sensed.

Article source: magnetostrictive displacement sensorhttp://xdij.cn